The hard work, time and craftsmanship that goes into a Drummonds bath

James Lentaigne of Drummonds spoke to Country Life's Giles Kime about how his company create baths that will last for generations.

With its roots in the restoration of antique British baths and brassware, Drummonds has a deep understanding of what it takes to create beautiful, high quality baths that will last for generations.

Thirty years after it was founded, Drummonds now has showrooms in London and New York – and baths in some of the most beautiful houses and hotels in the world.

Country Life spoke to the company's Creative Director James Lentaigne about the hard work, time and craftsmanship required to create a beautiful bathroom.

What sets a Drummonds bath apart?

Making a Drummonds bath requires a combination of craftsmanship, skill and accumulated experience that doesn’t just achieve the highest possible quality but also allows us to offer forms and finishes that could never be achieved with mass manufacture.

What possibilities does craftsmanship create when you make baths?

Craftsmanship provides almost infinite opportunities; we can make baths that are larger, thicker and more durable than anything on the market. Enamel powder is fused into the cast iron so that it bonds to create a stunning product that will last for generations. An example is the 14 hours a skilled craftsman takes to polish the exterior of the cast iron down, by hand, to create a beautiful and unique finish.

And what about brassware?

The lost wax casting process requires similar amounts of skill and hard work and ensures that each item is a beautiful one off. The process originated from the 3rd millennium BC and is an artisanal process used to create bronze ages sculptures. Today we use it to create bathroom fittings that are seen in the same light by many of our customers.

How important are materials?

The highest quality materials are completely integral to everything we make. We stop at nothing to track down the best materials from all over the world; the china clay is sourced in the Midlands, for example. They comply with stringent certification, such as our brass from California that complies with some of the most exacting requirements.

How has Drummonds succeeded in reviving the golden age of British bathrooms?

Our range is timeless, and as such works in a variety of environments. Some commercial projects highlight this classic environment in different settings, from some of the world’s most iconic projects such as Annabels Members Club, London, St Giles House in Dorset and Ballyfin Hotel in Ireland to Gleneagles in Scotland & Soho Houses around the world.

Tell us about Drummonds’ collaborations with Martin Brudnizki.

The best interior designers have a deep understanding of what makes a perfect design; having worked with Martin Brudnizki (whose most recent project is the interiors of the new Annabel’s private members club) on bespoke designs for his own projects we discovered that there was a real meeting of minds and we went on to develop highly successful designs together, including our Derwent lights and Ladybower vanity.

Exquisite houses, the beauty of Nature, and how to get the most from your life, straight to your inbox.

-

'Uncut Gems' and the mystery of the most significant collection of Tudor and Stuart jewels ever found in London

'Uncut Gems' and the mystery of the most significant collection of Tudor and Stuart jewels ever found in LondonAs the London Museum prepares to unveil the Cheapside Hoard in new premises on Smithfield, Will Hosie speaks to historian Victoria Shepherd about the story behind these precious jewels.

-

Repton: The 500-year-old school with a medieval priory whose story leads back to the kings of Mercia

Repton: The 500-year-old school with a medieval priory whose story leads back to the kings of MerciaThe medieval Augustinian priory within the curtilage of Repton School in Derbyshire links together the history of this great public school with the Anglo-Saxon era and the Kings of Mercia. David Robinson tells its story, with photographs by Paul Highnam for Country Life.

-

Reimagining the past at Vaughan

Reimagining the past at VaughanIn September 2025, leading designers shared their views on creating interiors with the capacity to last forever.

-

Tetrad: Over half a century of timeless good looks

Tetrad: Over half a century of timeless good looksSince 1968, Tetrad has employed a combination of traditional skills and the finest materials to make upholstered furniture that is designed to offer years of comfort.

-

Reimagining the past: A panel discussion with Vaughan

Reimagining the past: A panel discussion with VaughanAt Focus/25 later this month, Vaughan will host an inspiring talk at which leading names in antiques and interiors will explain why understanding the past is vital to designing for the future.

-

Star of the show: Rose of Jericho's paint created just for Country Life at RHS Chelsea

Star of the show: Rose of Jericho's paint created just for Country Life at RHS ChelseaOne of the highlights of Country Life's ‘outdoor drawing room’ at the 2025 RHS Chelsea Flower Show was a new paint colour created by Rose of Jericho,

-

Munder-Skiles and the art of exterior decoration

Munder-Skiles and the art of exterior decorationThe success of this project — which was awarded four stars by judges at the Chelsea Flower Show — demonstrates Isabella Worsley’s versatility as a designer.

-

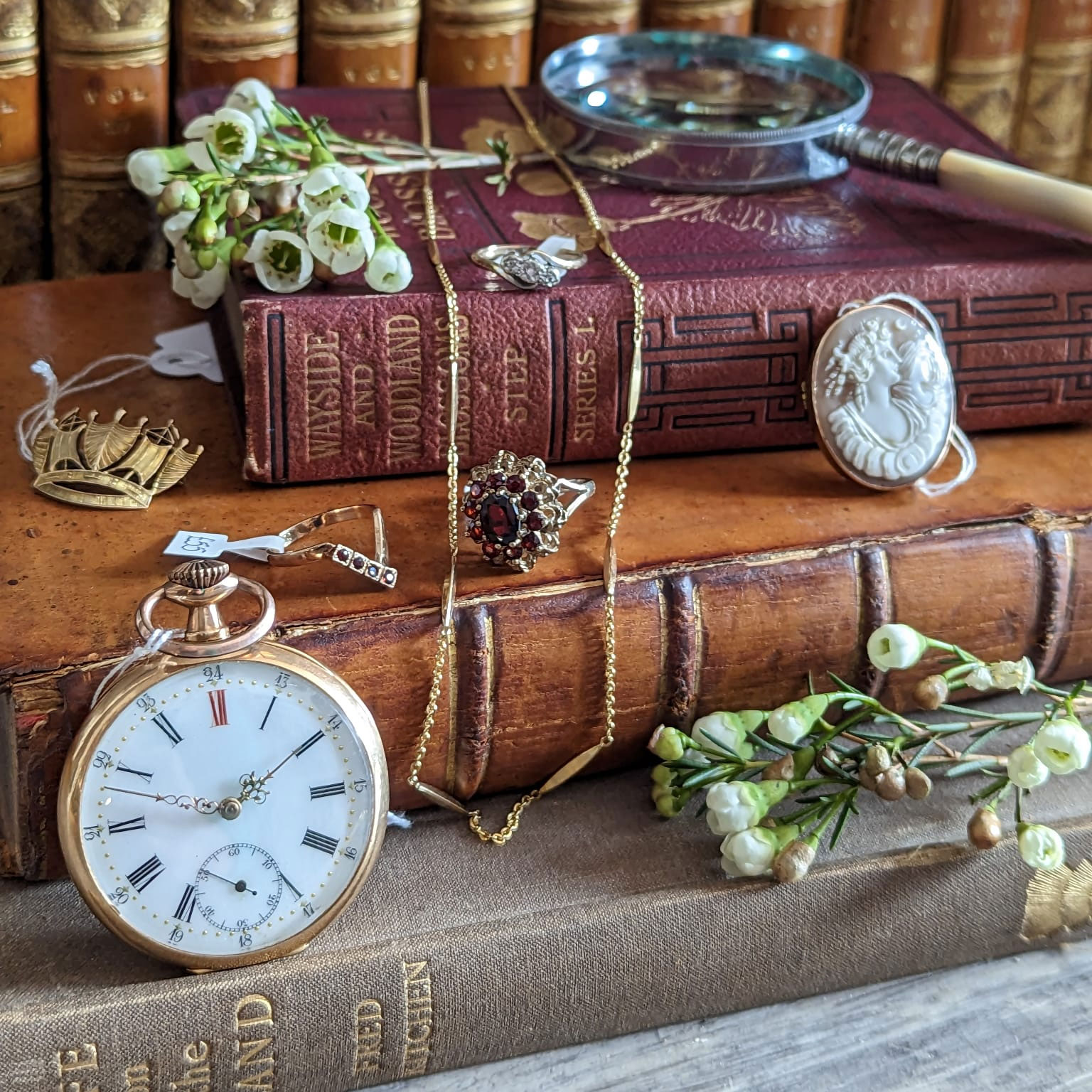

Sell your valuables with ease with The Antique Buying Collective

Sell your valuables with ease with The Antique Buying CollectiveThe Antique Buying Collective treats gold and silver as heirlooms, not scrap. From Victorian brooches to Georgian silverware, each piece is appraised for its history, craftsmanship .and charm, then thoughtfully rehomed through a trusted network. It’s a respectful approach, giving fine antiques the second life they so richly deserve

-

Reader Event: Designing spaces that feel like home

Reader Event: Designing spaces that feel like homeOn Wednesday, March 26, interior-design studio Sims Hilditch and George Smith, makers of luxury, handcrafted upholstered furniture, will mark the launch of new furniture designs for bedrooms in an event chaired by Country Life.

-

The Art of Lighting: Four of Britain's top designers share their best tips for choosing lighting

The Art of Lighting: Four of Britain's top designers share their best tips for choosing lightingAt a recent panel discussion hosted at Vaughan’s London showroom during Focus/24, interior designers Emma Pocock and Sarah Peake, lighting designer Jo Mann of Lighthouse Designs and Richard Smith of Vaughan shared their top 10 tips on choosing lighting.