In the frame: How English Heritage Buildings blend craftsmanship and technology

English Heritage Buildings combine traditional craftsmanship with state-of-the-art technology to offer high quality buildings at highly competitive prices.

English Heritage Buildings was founded by Mick Hook in 1990, following over of decade of restoring centuries-old oak frame farm buildings across Sussex. His idea was to use this traditional construction technique to manufacture new oak frames and he subsequently played a pivotal role in the revival of this time honoured style of building.

Mick’s son, Darren, took on the mantle in 2004 and he has continued to build on the foundations established by his father, taking it from an entrepreneurial outlet into the professional and highly successful organisation. Today, the business benefits from the huge amount of work that Mr Hook invested in innovation, quality and service. His first commitment was to attain BM Trada Q-Mark certification – a prestigious award, and English Heritage Building is the only oak frame manufacturer to have achieved it. Mr Hook’s commitment to the company’s continued development is in the aim of providing customers with the very highest quality product on the market, at the most competitive price.

What are the most of important things that the team at English Heritage Buildings has learnt over the last 30 years of crafting oak framed buildings?

English Heritage Buildings believes that in business it’s essential to focus on what you’re good at. By concentrating solely on the manufacture of oak frames, the team have been able to build on Mr Hook's expertise and to devise techniques and processes that enable it to create buildings that are world class. English Heritage buildings work with approved contractors on assembly, ground works and roofing who share their focus on quality while their team focus on crafting and engineering buildings of the highest possible quality.

Why are oak framed buildings enjoying a revival?

Oak is a timeless building material that strengthens with age and creates buildings that are extremely sympathetic to period buildings. There are also real benefits to off site manufacture; in the unpredictable and unregulated building industry, it offers much greater control over both quality and building schedules.

How have you used technology to transform the construction process?

English Heritage Building’s German engineered Hundegger K2i CNC machine is an example of state of the art technology that allows precision and speed that could never be achieved by hand. This, alongside all the checks involved in their BM TRADA Q-Mark standard, almost eradicates any errors within the manufacturing process and ensures each frame fits together like a glove when it is constructed on site.

What is the benefit of your 22 standard BM TRADA Q-Mark certification?

The 22 point process starts when the timber arrives at the English Heritage Buildings yard and is checked by its team of in-house timber graders who assess knot size, splits and bugs. Only the best quality timber is selected. Throughout the manufacturing process, the beams are checked at 20 minute intervals.

Joints are put together while still at our yard to ensure that they fit together perfectly when the building is constructed. Every component is thoroughly checked after it has all been manufactured and before it is delivered to a customer. The benefit of meeting these 22 standards is a better quality product both in strength and aesthetic. It also helps to prevent any errors within the manufacturing process.

How did English Heritage Buildings achieve Q-Mark certification?

Because it had never previously existed, English Heritage Buildings devised the standard and had it approved by BM Trada, the specialist in testing, inspection and certification. English Heritage Buildings documented the whole process from design to assembly and demonstrated how it meets, manages and maintains each of the 22 standards.

What help and advice does English Heritage Buildings offer with planning?

English Heritage Buildings work with a planning consultant who has many years’ experience in submitting planning applications for oak frame buildings, particularly listed buildings or those in conservation areas (as many of its customers’ properties are). This planning service has a 95% success rate on first time applications as the consultant has experience in the optimum ways to present cases to the local authority.

English Heritage Buildings — 01424 838643, www.ehbp.com

Exquisite houses, the beauty of Nature, and how to get the most from your life, straight to your inbox.

-

Renault 4: Retro, rewired, and ridiculously likeable

Renault 4: Retro, rewired, and ridiculously likeableMatthew MacConnell falls in love with a reimagined French classic.

-

Five of our favourite dog-friendly hotels — and they've all been approved by Geoffrey the dachshund

Five of our favourite dog-friendly hotels — and they've all been approved by Geoffrey the dachshundWe sent Jennifer George and her canine companion Geoffrey on a quest to find five of the best dog-friendly hotels in the south.

-

Reimagining the past at Vaughan

Reimagining the past at VaughanIn September 2025, leading designers shared their views on creating interiors with the capacity to last forever.

-

Tetrad: Over half a century of timeless good looks

Tetrad: Over half a century of timeless good looksSince 1968, Tetrad has employed a combination of traditional skills and the finest materials to make upholstered furniture that is designed to offer years of comfort.

-

Reimagining the past: A panel discussion with Vaughan

Reimagining the past: A panel discussion with VaughanAt Focus/25 later this month, Vaughan will host an inspiring talk at which leading names in antiques and interiors will explain why understanding the past is vital to designing for the future.

-

Star of the show: Rose of Jericho's paint created just for Country Life at RHS Chelsea

Star of the show: Rose of Jericho's paint created just for Country Life at RHS ChelseaOne of the highlights of Country Life's ‘outdoor drawing room’ at the 2025 RHS Chelsea Flower Show was a new paint colour created by Rose of Jericho,

-

Munder-Skiles and the art of exterior decoration

Munder-Skiles and the art of exterior decorationThe success of this project — which was awarded four stars by judges at the Chelsea Flower Show — demonstrates Isabella Worsley’s versatility as a designer.

-

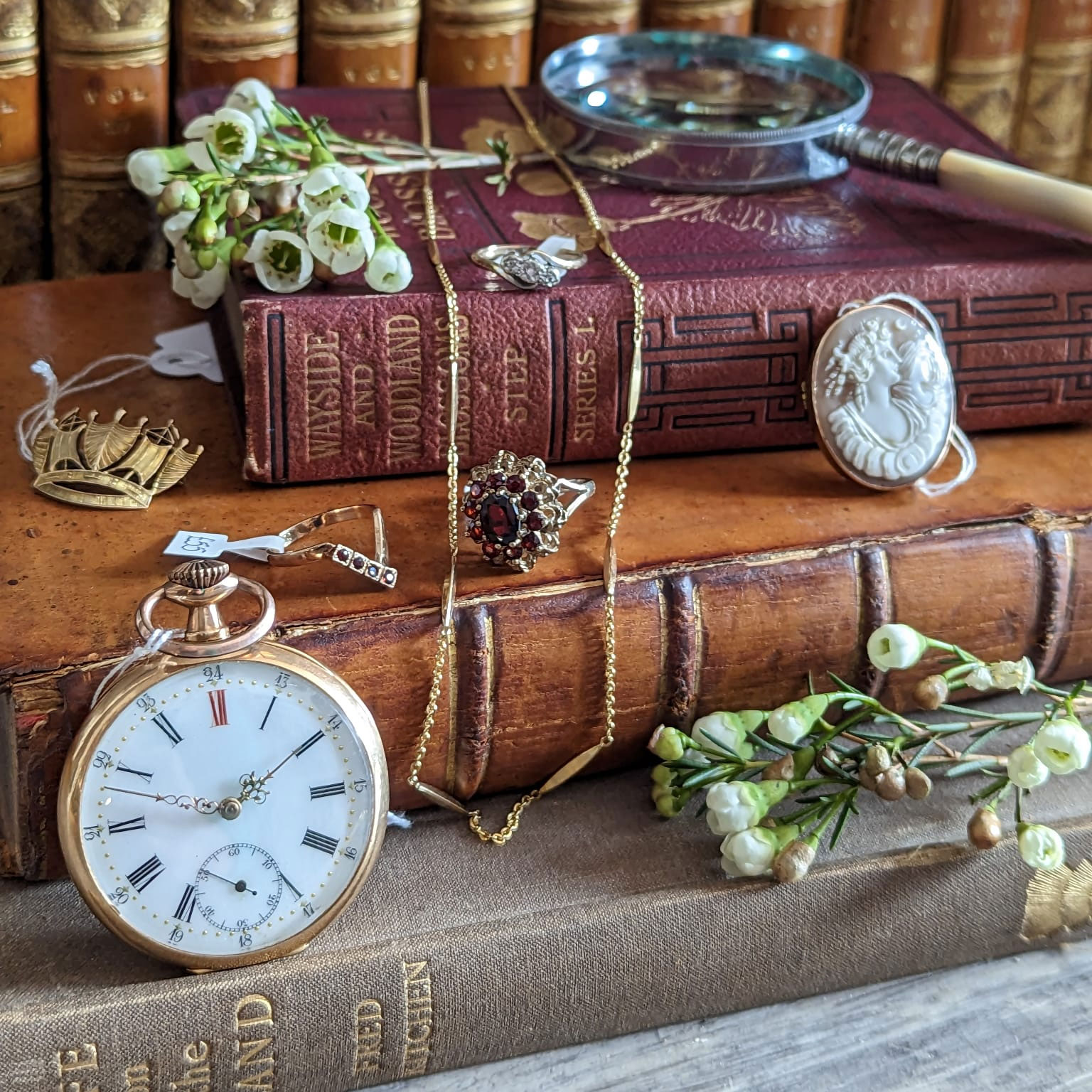

Sell your valuables with ease with The Antique Buying Collective

Sell your valuables with ease with The Antique Buying CollectiveThe Antique Buying Collective treats gold and silver as heirlooms, not scrap. From Victorian brooches to Georgian silverware, each piece is appraised for its history, craftsmanship .and charm, then thoughtfully rehomed through a trusted network. It’s a respectful approach, giving fine antiques the second life they so richly deserve

-

Great garden getaways

Great garden getawaysDiscover some of Britain’s finest gardens with a PoB Hotels break

-

Reader Event: Designing spaces that feel like home

Reader Event: Designing spaces that feel like homeOn Wednesday, March 26, interior-design studio Sims Hilditch and George Smith, makers of luxury, handcrafted upholstered furniture, will mark the launch of new furniture designs for bedrooms in an event chaired by Country Life.